Retractable Roller Cone Head for Auger Boring

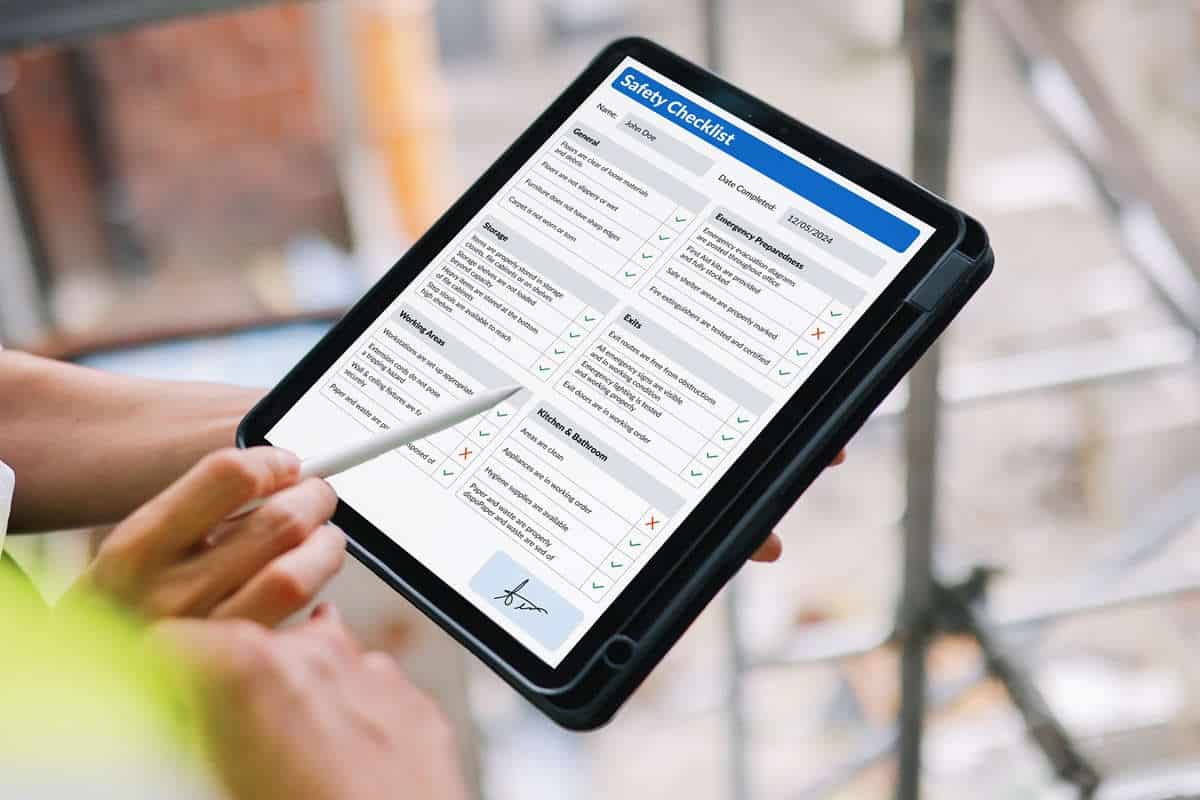

Chad Cox, Brent Scarbrough & Co., at the completion of a 200-ft bore using the Barbco retractable roller cone head.

Barbco is bringing to the market its new line of Retractable Roller Cone Heads (RCH) specialized to take on various hard rock ground conditions. Traditional roller cone heads from Barbco go back to the early 1990s. These heads were new at the time in the auger boring industry, their design proved successful, and they established a strong foothold in the market.

Traditional roller cone heads were great assets to bore contractors, but in the event you needed to assess downhole conditions, the heads were unable to retract and be pulled out of the casing. That problem was the catalyst to the evolution of Barbco’s BBC-55, Retractable Roller Cone Head.

The keyword here is retractable. In the event a contractor needs to assess downhole ground conditions, they can simply retract the cutting head, remove it, and proceed, like any traditional Barbco cutting head.

This provides contractors with unmatched versatility downhole, which is one of the most important things in the trenchless field. Due to ever-changing ground conditions, the RRC head could be advancing through solid or split face, hard rock ground conditions, and suddenly run into sticky clay which could render it inadequate.

The design of the RRC head gives you the ability to retract the head, assess downhole conditions, and change to a different style cutting head, if necessary. It’s also important to note that the ability to retract this head makes it easier to assess its overall condition, and service it if necessary throughout the bore process.

Not only does the retractable roller cone head offer extreme versatility, it also has ample cutting capability due to various roller-cone style options that are available. Barbco RRC heads can be tailored to match specific rock conditions on site, or general rock conditions, so that any bore contractor can decide for themselves when investing in extreme tooling.

“This new unique style roller cone head absolutely did its job. We encountered 27,000 psi hard granite and went in with the Barbco BBC-55 retractable roller cone head. This head made the course driving 200 ft containing line and grade at a perfect 1.00%,” said Chad Cox of Brent Scarbrough & Co., a Georgia-based underground contractor.

When utilizing a Barbco roller cone head, it is paramount to keep the roller cones cool. The roller cone head can be used in conjunction with Barbco’s air-way auger through the Hard Rock Drilling System, or connected directly to a pilot string via Guided Boring. Though these two cooling methods are preferred, adding multiple ½-in. water lines to the front of the lead casing will additionally suffice. Keeping the cutters cool will maximize the longevity and return on investment from the retractable roller cone head.

The overall capabilities of Barbco’s retractable roller cone heads offer contractors a versatile tool for cutting rock.