Excellence in Underground Awards Trenchless Technologies Winner

Rudd Ave Large Diameter Sewer Rehabilitation Project

[EDITOR’S NOTE: In each issue, Utility Contractor profiles NUCA’s Excellence in Underground winners (formerly “Top Jobs”.) The projects recognize challenging, innovative, or unique projects completed with excellent results. To nominate your project for an Excellence in Underground Award, visit:

https://www.nuca.com/excellenceunderground]

Midwest Mole was contracted by Ulliman Schutte and Louisville MSD to be the design-build contractor to rehabilitate approximately 2,800 lf of existing combined brick sewer in the historic Portland neighborhood of Louisville, Kentucky. The specified design parameters of the rehabilitation included the following:

- The rehabilitated pipe shall withstand a 25 psi internal pressure

- The rehabilitated pipe shall withstand external groundwater pressures at the 1937 Louisville Flood Elevation

- The design strength is to be independent of the existing sewer and that it is assumed that the existing sewer will no longer provide any structural capability

In addition to the age of the sewer, dating back to circa 1900, the project team had to deal with multiple obstacles in order to deliver a successful project including, working under/near an elevated portion of a federal highway, working near the McAlpine Locks and Dam along the Ohio River, working near a heavily traveled railroad, and working downstream of one of MSD’s Combined Sewer Overflow basins.

Upon inspection of the sewer, Midwest Mole determined the most buildable and economical solution would be to slipline the straight portion of the sewer and shotcrete the sweeping portions of the sewer. Midwest Mole retained FK Engineering as the design engineer and they worked together to develop a solution utilizing these two technologies. A bypass system was installed capable of 4 mgd of wet-weather flow.

In addition to Midwest Mole and FK Engineering, project team members included TRC LLC (shaft installation, access), Blue Tank Pump (sewer bypass rental), ProShot (shotcrete installation), Robinson Pipe Cleaning (sewer jetting and MH epoxy repair), and HOBAS Pipe. Ulliman Schutte was the design-builder.

Challenges and Innovative Solutions

Midwest Mole self-performed the approximately 1,800 lf with diameters ranging from 120 to 126 in. slipline utilizing 110-in. SN 72 HOBAS as the product pipe. A detailed lay schedule was developed, ensuring the final position of the liner within the sewer allowed for the 18 existing laterals ranging from 6 to 48-in. and two 48-in. manholes to be reinstated without cutting through a joint in the newly installed HOBAS pipe.

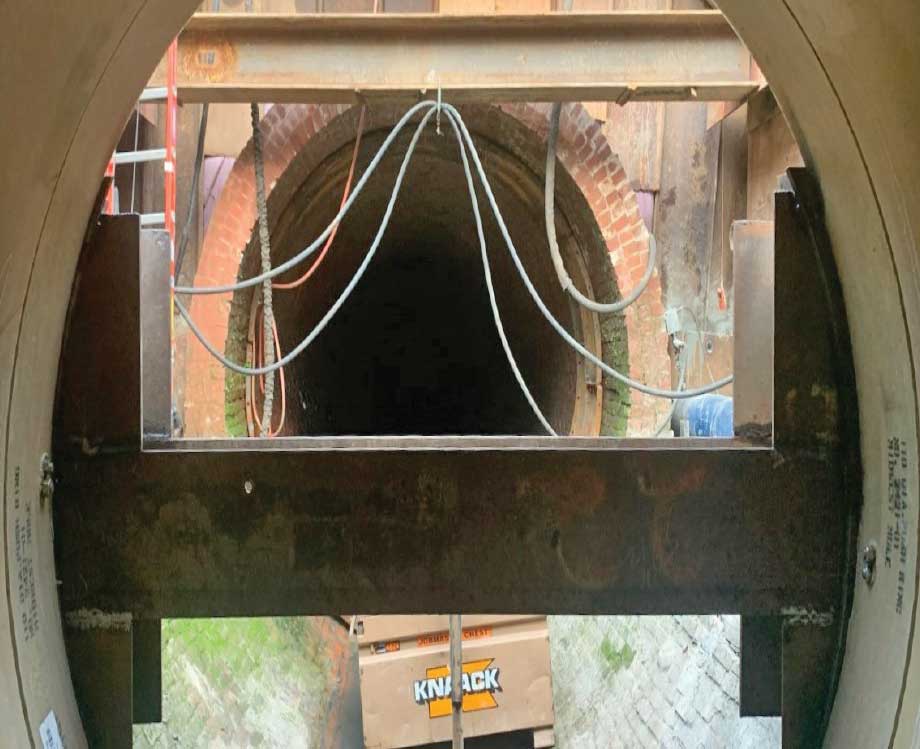

Due to limited access, the team designed an access shaft to facilitate pushing the HOBAS pipe in both directions. After installing the access shaft and cleaning the sewer, a custom-built jack frame was set in the shaft that utilized 13-ft stroke hydraulic cylinders to facilitate jacking the 20-ft segments of HOBAS. During the mandrelling, it was discovered that there was an approximately 70-lf section of the existing sewer that included a small irregularity – a slight “S” curve. While sliplinning through the irregular section, the jacking pressures rose significantly. Working with FK Engineering to identify a solution, crews removed one layer of brick from the existing sewer to push the HOBAS through the irregular section while keeping the joint deflection within specification and used wood cribbing to keep the HOBAS joints within specification.

Benefit to the Client and Community

Despite the numerous obstacles that were encountered, Midwest Mole and its partners completed the project within its original schedule and below its original target budget without any recordable or lost time accidents. This not only benefited Louisville MSD and Jefferson County, but also their ratepayers.

“As a public entity, MSD is tasked with being diligent stewards for our ratepayers. The collaborative nature of this project has proven to be fully supportive of this mandate. Despite the numerous obstacles to overcome, the project was completed within its original schedule and below its original target budget without any recordable or lost time accidents. We are confident that the rehabilitated sewer will provide a safe reliable sewer asset for the foreseeable future. The project not only succeeded, it surpassed all expectations by every measure in terms of solution optimization, collaboration, flexibility, quality, delivery time, cost savings, impact to community/stakeholders, partnering and teamwork,” wrote MSD’s Brandon Flaherty, PE, Engineer III.

By rehabilitating the pipes, the life expectancy of the sewer is extended and the city can provide a safe, reliable sewer asset for the foreseeable future.