The Right Pipe

There are plenty of options to choose from when looking for the appropriate pipe for installing or replacing underground infrastructure. To get started in your decision-making process, take a look at these eight types of pipe to help determine the right one for your next project. These are just snippets of information, so be sure to further your research at the websites cited below.

There are plenty of options to choose from when looking for the appropriate pipe for installing or replacing underground infrastructure. To get started in your decision-making process, take a look at these eight types of pipe to help determine the right one for your next project. These are just snippets of information, so be sure to further your research at the websites cited below.

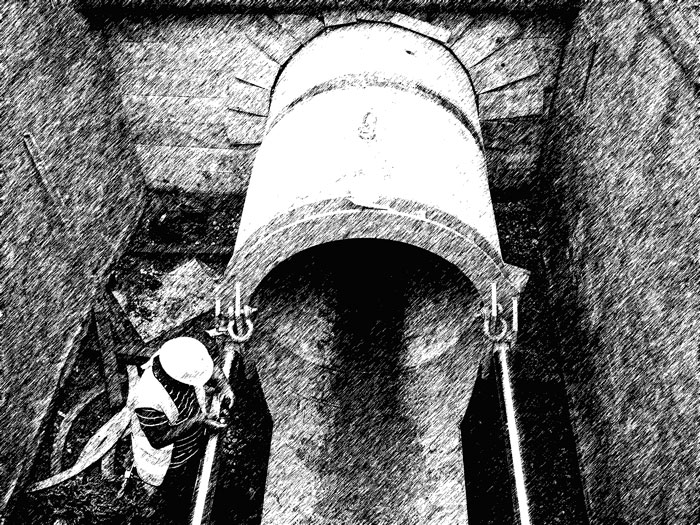

Concrete Pipe

with a design life in excess of 100 years, is ideal for jacking and microtunneling applications where pipe with high strength is needed for the jacking forces. Box culvert sections can be used for applications where square or rectangular shapes may be more beneficial, such as low clearance areas, pedestrian tunnels, etc. Pre-cast concrete pipe is delivered in pre-cast units that are ready for installation, and typically has a bell-and-spigot joint using a rubber gasket when used in trenchless applications. Circular reinforced concrete pipe is available in sizes from 12 to 144 in., and elliptical and arch shapes are also available for locations with limited vertical or horizontal clearance. For more information, visit www.concrete-pipe.org.

Ductile Iron Pipe

ranges in diameter from 3 to 64 in., with an indefinite design life when properly installed. This type of pipe works well for installations that require the pipe to have tremendous columnar and tensile strengths, in gravity to high-pressure applications and installations that require a robust pipe. It’s commonly delivered in 18- or 20-ft lengths; however, shorter lengths can be obtained by cutting the pipe. Ductile iron pipe is joined by push-on gasketed joints with allowable deflection up to a 5-degree deflection, as well as push-on flexible restrained gasketed joints and other proprietary compression ring gasketed joints that facilitate trenchless applications. For more information, visit www.dipra.org.

Fiberglass Reinforced Pipe

is available from 18 to 158 in. in diameter, depending on the manufacturer and boasts a design life in excess of 50 years. This pipe is best suited for potable water transmission, force main or gravity sewer systems and all applications where there is a corrosive carrier or external environment. The typical delivered length is 20 ft; however, both short sections (e.g., 5 and 10 ft) and longer lengths of up to 40 ft are available to minimize the number of joints. Fiberglass pipe uses a number of different gasket-sealed joints. Typically, the pipe joints are push-together coupling or bell-and-spigot joints. Restrained joints are available from some manufacturers for curved or otherwise stressed pipe sections. For more information, visit www.fiberglasstankandpipe.com.

High Density Polyethylene (HDPE)

is a smart choice for all underground utilities including gas, water, sanitary sewer, electrical and communication duct, storm sewer and water service connection. Polyethylene pipe is produced in straight lengths up to 50 ft long and coiled in diameters up to 6 in. With HDPE, heat fusion is the preferred method of joining. However, pipe can be either heat fused or mechanically joined with a variety of couplings. It has a range of available diameters, including: 1/2 to 65 in. (solid wall); 2 to 60 in. (corrugated); up to 120 in. for spiral-profile wall and 1/2 to 3 in. for crosslinked PE (PEX) pipe. The polyethylene pipe industry estimates a service life for HDPE pipe to conservatively be 50 to 100 years. For more information, visit www.plasticpipe.org.

Polymer Concrete

offers available diameters ranging from 8 to 144 in. and a design life of 100-plus years. It’s ideal for sanitary sewer or industrial sewer service where conditions require corrosion protection. Polymer concrete pipe is typically delivered in 8- or 10-ft lengths. One-meter lengths are available for pilot tube installation methods. Standard joint for jacking installations incorporates a double spigot joint joined by a flush compression fit fiberglass or stainless steel collar. The collar mates against the gasket that’s firmly joined to the pipe wall. The joint meets the requirements of several ASTM standards. For more information, visit

www.polymerpipe.org.

Polyvinyl Chloride (PVC) Pipe

works well for water distribution and transmission mains, gravity sanitary sewer systems, force mains, reclaimed water (purple pipe) and storm sewers. It’s delivered in standard lengths of 20 ft for pressure pipe and sewer pipe lengths can be 14 or 20 ft long. PVC pipe in municipal applications for open-cut installations uses deep socketed bell-and-spigot joints. Bell-and-spigot pipe can be restrained with either external or integral joint restraints. Gasket joint PVC pressure pipe is available in diameters from 1.5 to 48 in. and gasket joint PVC non-pressure pipe is available from 4 to 60 in. According to a 2005 AWWA Research Foundation study, corrosion-proof PVC pipe design life is in excess of 110 years. For more information, visit www.uni-bell.org.

Steel Pipe

is a suitable solution for water and wastewater transmission, gas and oil transmission, water well casing, pile driving and caisson sleeves. It is available in diameters 4 in. and larger with virtually an unlimited choice of fitting and special fabrications possible. Steel pipe that may be hydrostatically tested is generally supplied in standard laying lengths of 20 to 60 ft. The most common method of assembling steel pipe is by field welding or bell-and-spigot joints with rubber O-ring gaskets. Steel pipe’s design life is based on the mechanical strength of steel, which is fully elastic and not time dependent. If properly installed, with the appropriate lining and coating, steel pipe with the addition of electrical bonding and cathodic protection (if required) can last indefinitely. For more information, visit www.steeltank.com.

Vitrified Clay Pipe (VCP)

features a design life of more than 200 years and is available in diameters ranging from 4 to 42 in. for open-cut and 8 to 48 in. for trenchless. VCP is great for gravity flow sanitary sewers and is ill suited for pressure applications. It is available in a variety of stock or custom lengths, depending on diameter, with a maximum length of 10 ft. In open-cut applications, VCP is joined by factory-applied bell-and-spigot elastomeric compression joints. Trenchless calls for low-profile compression joints utilizing stainless steel collars. For more information, visit www.ncpi.org.