Back to Basics: Sloping and Benching

I doubt there is an underground contractor that does not realize the importance of protecting workers from a cave-in when employees are working in a trench. In fact, it is an OSHA requirement that all workers in trenches 5 ft or more in depth (some states 4 ft deep) must be protected by a trench protective system (sloping, shoring and shields). When the depth of a trench is less than 5 ft, OSHA still requires the competent person (CP) to make a judgment call based on the conditions at the jobsite. For example a vertical trench wall that is made up of a wet, sandy flowing soil and only 3 or 4 ft deep is dangerous and could cave in causing a worker to be injured, therefore the CP must take action to protect the workers.

There are several types of protective systems that may be used to comply with state and OSHA requirements. They include trench shields (boxes), shoring and, of course, the old reliable sloping or benching. However, the method that appears to be the simplest to understand and use — sloping and benching — often results in citations for non-compliance because the slope or bench is improperly cut or sloped.

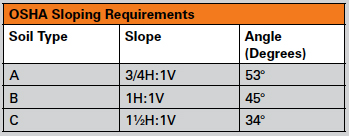

So far, so good! However, what should the slope of the soil be for type C soil and how do you know when the slope is correct? OSHA requires type C soil to be sloped at 1½H:1V and it cannot be benched. This means that the slope must be cut back 1½ ft horizontally for every 1 ft of depth. The 1½:1 is equal to an angle of 34 degrees from the horizontal. As for type A soil, the slope must be ¾H:1V, or 53 degrees, and type B soil, which is the easiest one to understand, is 1H:1V or 45 degrees from horizontal.

Rest assured if an OSHA Compliance Safety and Health Officer (CSHO) visits your jobsite and sees sloping has been selected as the protective system, he or she will measure the trench and determine the slope. Some CSHOs will use a rod and inclinator to determine the slope in degrees and others may just use simple calculations to calculate the slope. Obviously using a rod and inclinator is the easiest and fastest way to determine slope. However, calculating the slope is also very simple. For example, if the trench is 6 ft deep and 20 ft wide across the end of the trench and the bottom of the trench is 2 ft wide, the slope can be calculated as follows:

Horizontal distance = 20 ft – 2 ft ÷ 2 = 9 and the Vertical depth = 6 ft; Slope = 9 ÷ 6 = 1.5 to 1, which is the slope needed for type C soil.

As I mentioned earlier, an inclinator can be used. An inclinometer, clinometers, tilt meter or indicator is an instrument used for measuring angles of slope or tilt with respect to gravity or horizontal plane. In its simplest form, it is a protractor with an indicator that will point to the angle of slope as the protractor rotates from the horizontal plane to the line of slope. Simple inclinometers can be purchased from most building supply stores. Smart levels will also measure slope.

In addition, if you own a smartphone or tablet you can download an inclinometer app. Some are free and others cost a dollar or two. By placing a straight rod or piece of lumber on the slope and then resting the edge of your device on the rod or lumber you can determine the slope. To locate an inclinometer for your device, all you have to do is search for apps using the term inclinometers, clinometers or tilt meter.

If your company uses sloping as a protective system for trenches, an inclinometer is the only accurate way to ensure the slope angle is equal to or less than the required angle. By using any of these inclinometer devices, companies that use sloping for a protective system can ensure that the slope is correct for the soil type.

Sloping as a Protective System

Sloping the trench wall to the proper angle is definitely an acceptable method, and sometimes the only method, which may be used to protect workers in a trench or excavations. However, it is important you realize how much dirt must be moved and how costly it can be considering the price of fuel, operator time, fill, compaction and other variables which can add up quickly. Many underground construction contractors have come to realize that it can be less expensive to rent or purchase trench shields or aluminum hydraulic shoring systems especially when installing miles of pipe or cable. For a better idea of what it costs to move dirt, try this Slope Calculator: www.lhsfna.org/index.cfm?objectID=CA255E3B-D56F-E6FA-90B09A69EAD41254.

Trench Safety

There are many hazards that could exist around an underground utility construction site and the one that is most likely to cause a fatal injury is a trench cave-in. This is why it is so important to ensure that proper protective systems — sloping, shoring and shields — are always used and used properly.

We have seen the number of trench fatalities drop over the years, but unfortunately workers are still being buried alive. The only way we can prevent this is to ensure that every trench is equipped with a protective system of one form or another.

George Kennedy is NUCA Vice President of Safety.