Conquering COEXPO

After attending the NUCA 2014 Convention, head on over to the Las Vegas Convention Center for CONEXPO-CON/AGG, March 4-8. Every three years, the massive trade show ascends upon Sin City to highlight the latest and greatest products and technologies the construction industry has to offer. This year’s show will feature 2,400-plus exhibitors spread out over 2.3 million net sq ft of exhibit space (see the handy map below to find your favorite companies) and is expected to attract more than 130,000 attendees from around the world. The event also boasts a fantastic comprehensive education program with tracks covering topics such as Business Management Best Practices, Earthmoving and Site Development and Safety and Regulations, to name a few.

After attending the NUCA 2014 Convention, head on over to the Las Vegas Convention Center for CONEXPO-CON/AGG, March 4-8. Every three years, the massive trade show ascends upon Sin City to highlight the latest and greatest products and technologies the construction industry has to offer. This year’s show will feature 2,400-plus exhibitors spread out over 2.3 million net sq ft of exhibit space (see the handy map below to find your favorite companies) and is expected to attract more than 130,000 attendees from around the world. The event also boasts a fantastic comprehensive education program with tracks covering topics such as Business Management Best Practices, Earthmoving and Site Development and Safety and Regulations, to name a few.

Below, check out a sliver of the companies that will be at CONEXPO-CON/AGG and plan accordingly to see all the new machines, products and technologies they have to offer to help boost your business and give you an edge in 2014 and beyond.

Volvo

Volvo

North Hall, Booth #10951 and Gold Lot, Booth #1300

When space is in short supply, the new ECR58D and ECR88D short swing radius compact excavators from Volvo Construction Equipment are in their element. Even with a compact size, the D-Series excavators boast digging performance, breakout and tearout forces and lifting capabilities that rival their larger counterparts. These machines also feature engines that offer superior performance and reduced fuel consumption. Manueverability and productivity are also optimized on these compact machines. Both models feature automatic two-speed travel for superior traction and hydraulic travel pedals for easy and accurate track control.

Kobelco Construction Machinery USA

Kobelco Construction Machinery USA

Silver Lot, Booth #4408

Kobelco’s 2014 CONEXPO exhibit will offer show attendees an equal amount of product information and fun, including a first glimpse of the company’s all-new line of demolition equipment and its SK55 model crawler excavator. The company’s 2014 exhibit serves as Kobelco’s homecoming to CONEXPO as an independent brand. Products on display will include 14 of Kobelco’s crawler excavator models, starting with their compact short radius models up to their production-sized SK500 model, plus three all new demolition machines and three products from Hino, a partner manufacturer who supplies engines for Kobelco products.

Hyundai Construction Equipment

Hyundai Construction Equipment

North Hall, Booth #10052

Hyundai’s R35Z-9 excavator is ideal for tight, confined jobsites and designed for maximum performance. The 8,050-lb R35Z-9 is powered by a reliable 26.5-hp, Tier 4-certified Yanmar 3TNV88 engine. The machine has a dig depth of 10 ft, 4 in. and a bucket breakout force of 7,050 lbs. The R35Z-9 offers a tail swing radius of just 2 ft, 10 in., allowing for efficient operation on sites where space is limited. Hyundai’s R35Z-9 features an advanced hydraulic system designed to give the user super-fine touch and top-level controllability, allowing the excavator to be nimble and accurate while operating in congested areas.

Yanmar

Yanmar

Yanmar’s new ViO45-6A zero tail swing excavator uses 30 percent less fuel than its predecessor and still has a maximum digging depth of 12 ft, 3 in. Powered by a Yanmar 4TNV88 Tier 4 Final diesel engine that delivers 39 hp, this machine doesn’t back down from any job. It has standard ECO and Auto-deceleration modes, and a digital Smart Assist control system that stores up to three months of operational and maintenance support information that can be monitored in one centralized location. It’s available with a canopy or enclosed cab with heat and A/C.

Ditch Witch

Ditch Witch

South Hall 1, Booth #62216

With its 60,000 lbs of thrust and pullback and 9,000 ft-lbs of rotational torque, the Ditch Witch JT60 All Terrain horizontal directional drill gives operators the flexibility of a smaller footprint drill without losing power. The machine’s patented two-pipe drilling system gives more power to the bit than any other rock-drilling system in its class, says the company. The JT60 All Terrain will come factory-equipped with the proven Ditch Witch GPS offering at no additional charge. Users can remotely view engine hours, operational hours, service reminders and various other performance criteria while gaining awareness into operator practices and idle time.

Vermeer

Vermeer

South Hall 1, Booth #61716

Vermeer’s D36x50DR Series II horizontal directional drill features a rod-in-rod design with dual threaded makeup. With a rated rotational torque of 1,500 ft-lbs, the inner rod powers the downhole tri-cone as the outer rod provides steering and backreaming rotation. The dual threaded rod design also enables a drilling fluid course between the inner and outer rod, as well as through the inner rod, to help meet the volume requirements needed for efficient removal of the cuttings. An automated rod makeup and breakout system can be utilized to reduce manual operator interface, though it is equipped with a manual override for operators who prefer it.

Case Construction Equipment

Case Construction Equipment

North Hall, Booth #11722

Case introduces its new Tier 4 Final TR270 Alpha Series compact track loader, an updated 74-hp model that increases bucket breakout force (7,270 lbs), torque (232 ft-lbs) and hydraulic flow (standard: 24.2 gpm; high-flow: 32.4 gpm) compared to the previous model. The TR270 features a cooled exhaust gas recirculation (CEGR) engine with a particulate matter catalyst, which is made up of a diesel oxidation catalyst (DOC) and a high-efficiency flow-through filter. This solution is efficient and maintenance free as it does not require manual regeneration or filter replacement. The TR270 offers a new EZ EH (electro-hydraulic) setup menu that features nine preset speed and control settings that can be adjusted on the fly.

John Deere

John Deere

North Hall, Booth #12621

The new E-Series line of skid steer loaders and compact track loaders from John Deere feature enhancements and improvements that were developed after extensive input from customers. The large-frame units feature a flat floor design with 25 percent more foot room than previous models, giving operators more comfort in the cab. Lower noise levels also contribute to reduced operator fatigue and increased productivity. All models include low-effort electro-hydraulic (EH) controls for additional comfort and ease of operation. The EH controls are available for ISO, H and foot control patterns. In addition, the E-Series features an option to allow the operator to switch between all three previously mentioned industry control patterns.

Caterpillar

Caterpillar

Gold Lot, Booth #1015 and North Hall, Booth #10915

Caterpillar is rolling out four new D Series skid steer loaders and updating two current D Series machines to create the new D Series line — featuring a completely redesigned cab with first-in-class features, new lift arm design for improved sight lines and increased engine performance. The Cat D Series line now encompasses six skid steer loader models ranging in rated operating capacity from 1,800 to 3,700 lbs. The 236D and 242D are mid-size frame models and can be as narrow as 60 in. The 236D, 242D, 246D and 262D feature an electronically controlled 3.3-liter engine that meets Tier 4 Final emissions standards.

Terex

Terex

Gold Lot, Booth #1047

Featuring a four-cylinder, turbocharged Perkins 804C-33T diesel engine, the new 71-hp Terex PT-75 compact track loader is the newest member of the Terex line of Tier 4 Interim compliant compact construction equipment. Boasting a narrow machine width (70 in.), the PT-75 track loader can easily maneuver and operate in confined or congested worksites. Its purpose-built chassis is designed to be a heavy-duty machine within a compact package. Proving it has the power and productivity to get the job done, the PT-75 has 178.5 ft-lbs of peak torque, a tipping load of 6,200 lbs — with a 3,100-lb operating capacity at 50 percent tipping load capacity — and a lift height of 125 in.

McLaughlin

McLaughlin

Central Hall C1-C2, Booth #31125

The Vermeer VX 50-500 vacuum excavator by McLaughlin features Tier 4 Final engine technology and a new engine enclosure to help reduce engine noise levels and vibration. Operator-friendly enhancements include a large access door to the engine enclosure to provide improved accessibility. Contractors can also lock the enclosure doors, helping to deter potential vandalism. An improved external hydraulic door opens at an 85-degree angle, allowing for easier and more rapid dumping and cleaning of the spoils tank. A patented mechanical cam-over locking system provides a 360-degree positive door seal, even under reverse pressure, without additional clamping requirements.

IMT

IMT

Central Hall C1-C2, Booth #31125

The Vermeer VX 50-500 vacuum excavator by McLaughlin features Tier 4 Final engine technology and a new engine enclosure to help reduce engine noise levels and vibration. Operator-friendly enhancements include a large access door to the engine enclosure to provide improved accessibility. Contractors can also lock the enclosure doors, helping to deter potential vandalism. An improved external hydraulic door opens at an 85-degree angle, allowing for easier and more rapid dumping and cleaning of the spoils tank. A patented mechanical cam-over locking system provides a 360-degree positive door seal, even under reverse pressure, without additional clamping requirements.

Doosan Portable Power

Doosan Portable Power

Gold Lot, Booth #1501

Doosan Portable Power is introducing the industry’s first Tier 4 Final air compressors in the form of its most widely used models — the P185 and C185. With 100 psi at 185 cfm, the P185 and C185 meet the needs of a variety of applications, from powering handheld air tools, to sandblasting, sprinkler and irrigation line blow-out, cable laying and pipeline testing. After extensive testing and review, Doosan Portable Power selected a 49-hp Deutz D2.9 L4 electronic engine with DOC-only after-treatment to power the C185 and P185. The P185 and C185 deliver nine and seven hours’ runtime at 100 percent load respectively.

Minnich

Minnich

South Hall 1, Booth #62139

The Hornet utility drill is an ergonomic solution for drilling gas leak detection and extraction holes. Designed with the operator in mind, The Hornet’s patent-pending frame and feed cylinder absorb drill vibrations, lowering operator fatigue and increasing jobsite productivity. Lightweight, compact and portable, The Hornet is ideal for drilling through a variety of materials including concrete, asphalt, brick and dirt. The Hornet boasts a long list of time-saving and safety features, including spring-loaded squeeze grip controls and a frame that feeds the drill in and out of the hole, allowing the operator to stand in an upright position.

Leading Edge Attachments

Leading Edge Attachments

Central Hall 1, Booth #31040

Leading Edge Attachments Inc.’s patented Multi-DigNRip Bucket can replace hammers, blasting and rock trenchers, offered specifically for high production rip-and-load applications where a wider rock bucket is required. The Multi-DigNRip Bucket is a combination of the high force producing Multi-Ripper Bucket and the high capacity of the proven DigNRip Bucket. The Multi-DigNRip Bucket utilizes the world-wide patented “SHARC” (SHanks on an ARC) Technology, meaning that the bucket functions similarly to that of a trencher except it uses the hydraulic excavator rolling action to rip. The staggered ripper teeth fracture the substrate in sequential order, so the maximum breakout force is always applied sequentially to each tooth.

Kubota

Kubota

Central Hall C1-C2, Booth #30004

Kubota’s new 6-in-1 blade for its KX040-4 compact excavator can be angled to the right or left to push soil to the side as the machine moves forward, eliminating the need for repetitive repositioning at right angles when backfilling trenches. The blade’s capacity is increased almost 3/4 cubic yards over the standard blade. The blade angles a wide 25 degrees to help the spoil to slide off into the trench much better, improving backfilling time by as much as 35 percent. And with the tilt function, contractors are able to shape foundation edges for runoff, then come in and complete the slopes and swales for ample water drainage and a professional look.

John Deere Power Systems

John Deere Power Systems

South Hall 4, Booth #83718

John Deere Power Systems (JDPS) will display its Tier 4 Final off-highway diesel engines at CONEXPO-CON/AGG 2014. JDPS will showcase 2.9- to 13.5-liter engines that deliver responsive performance, reliable uptime and a low cost of operation. For Tier 4 Final, John Deere continued with its planned approach by developing the Integrated Emissions Control system, which encompasses a variety of after-treatment and emissions-reduction component combinations. Integrated Emissions Control system technology configurations are tailored to meet regulations and customer needs in each power range. All John Deere Integrated Emissions Control system configurations are designed to meet the demands of off-highway applications.

Pump It Up — The Search for the Right Pump Begins Here

Griffin

Griffin

Central Hall, Booth #40604 and Silver Lot 3, Booth #5168

Griffin’s hydraulic submersible pumps are available in axial flow, material handling and trash-handling models. The pumps range from 4 to 24 in. and are designed for handling volumes of water up to 20,000 gpm and head conditions up to 140 ft. The impellers can handle solids up to 3 in. They are ideal in high suction lift applications such as sewer bypass jobs, open pumping, sumping, dewatering of construction excavations and flood control. Griffin’s material handling pumps are designed to fit in standard manholes for sewer bypass operations and liquids with heavy trash and solids content.

Thompson Pump

Thompson Pump

South Hall 1, Booth #62129

The 4JSCM pump is part of the compressor-assisted JSC pump series. This trailer mounted, automatic priming, centrifugal pump provides flows up to 1,450 gpm and heads up to 130 ft. The 4-in. pump handles solids up to 3 in. and is ideal for sewer bypass pumping applications, emergency flood response and any other applications that require the transfer of liquids that contain solids. It is equipped with the exclusive Enviroprime System which provides reliable, automatic priming with the environmental advantage of not spilling pump fluids during initial priming and continued priming throughout operation.

Gorman-Rupp Pump Co.

Gorman-Rupp Pump Co.

Central Hall C3-C5, Booth #50077

The PAH10A60C-C18 is a heavy-duty, priming assisted pump model ideal for mining, quarries and other high-head installations where lifts are required. Flow rates are up to 6,500 gpm, and total dynamic heads up to 575 ft. This pump is capable of passing up to 2-in. diameter spherical solids. This 12-in. x 10-in. pump model is driven by a 755-hp, Tier 4 Interim Caterpillar C18 charge air cooled, two-staged turbocharged diesel engine power unit. The model is also furnished with an auto-start control panel and float switch assembly.

Talkin’ Tech — Check Out These Software and Technology Companies to Boost Your Productivity

Foundation Software

Foundation Software

South Hall 2, Booth #64622

FOUNDATION job cost accounting and project management software continues to evolve to meet the needs of contractors. With hundreds of new features, FOUNDATION is expanding contractors’ capabilities in the field and the office. Some recent enhancements to the system include: FOUNDATION mobile’s new Timecard Approval feature, which helps project managers verify data quickly and easily; a Document Imaging and Routing feature, where users can use e-mail correspondence between the originator of documents and project managers to track the approval process; and a Project Management feature where users can e-mail scanned documents with submittals, RFIs, transmittals and more.

HCSS

HCSS

North Hall, Booth #11956 and South Hall 2, Booth #64528

The HeavyJob Mobile Apps from HCSS helps cut foremen’s data entry time in half and gets daily job costs and production results in less time. Entering time card information is fast and easy with the ability to import crews or copy from previous time cards — often taking less than 5 minutes to complete. More than 2,100 field personnel now use the mobile apps to document everything, including daily diaries, photos, weather, quantities, safety meetings, fuel, subcontractors and materials. HCSS Mobile Apps are compatible with iOS and Android devices, and they work offline so an Internet connection is not required.

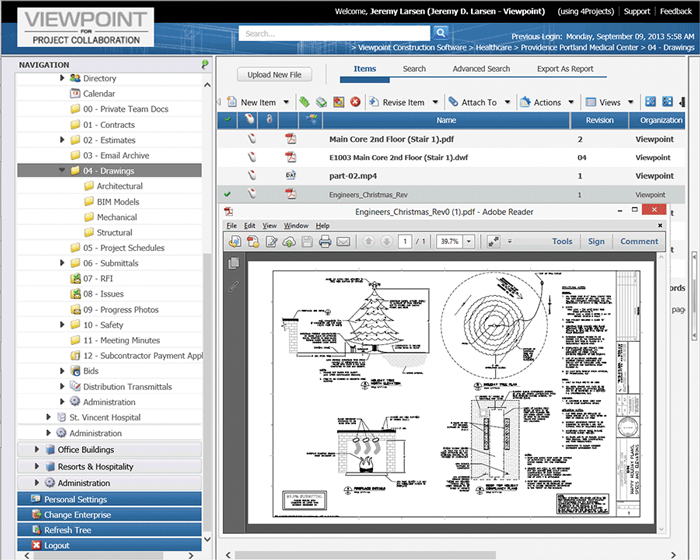

Viewpoint Construction Software

Viewpoint Construction Software

South Hall 2, Booth #65001

Viewpoint For Project Collaboration provides an online collaborative solution to help teams increase project control at every stage of the project lifecycle. Extending a technology platform with new software solutions can sometimes be a complex and frustrating experience. Viewpoint has eliminated that potential headache by delivering Viewpoint For Project Collaboration as Software as a Service (SaaS) — meaning users access and use the software online via any Internet connection. There’s no software to install, no costly or specific IT infrastructure to buy — just a low monthly payment. This approach ensures that business-critical applications can be deployed in a cost-effective, scalable, secure and risk-reducing manner.

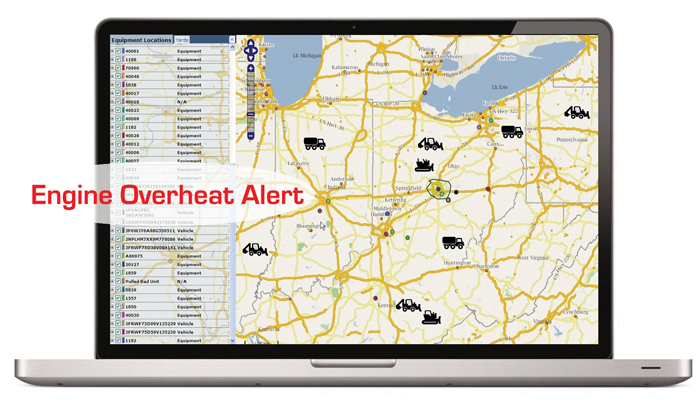

DPL Telematics

DPL Telematics

South Hall 2, Booth #65023

The TITAN Equipment Monitoring System is the complete tool for equipment owners to increase asset profitability and productivity, while decreasing the costs and risk of theft. The award-winning solution now includes a CAN Bus and OBDII Interface, which allows managers to remotely monitor and access critical information on their machines, such as: fuel consumption; RPM; engine torque and operating speed; idle vs. work time; temperatures and pressures; and diagnostic fault codes. The TITAN empowers the equipment owner to remotely shut down their machines, wirelessly locate them any time via GPS, collect hour meter readings and track hour based service intervals.