What’s the Scoop: Komatsu Excavators

From digging and backfilling to moving and placing pipe, the excavator is the go-to machine for utility contractors. To highlight these hard-working pieces of iron (as well as the companies that construct them), we’ve gathered the histories, product offerings and specs for the biggest names in the marketplace.

Over the next 10 pages, learn all about the product lines of the most popular excavator manufacturers in North America — from Caterpillar and John Deere to Komatsu and Volvo. Compare specs of different models or simply discover the beginnings of a brand you love. There are even insights and advice from industry insiders to aid in purchasing decisions and maintenance matters. Sit back, relax and dig in.

Pam Kleineke is managing editor of Utility Contractor.

Komatsu America Corp.

A Full Line of Options to Suit Any Line of Work

Since the late 1960s, Komatsu has led the hydraulic excavator market toward many machine advancements that have now become industry standards. The company currently produces a full line of excavators from small short-tail utility machines to large models suited for high-production, heavy-duty applications. Komatsu’s mid-size excavators, which largely serve the utility market, are its core machines. These high-performance excavators are on traditional construction sites and are also used in site prep and development, as well as underground and utility pipeline work.

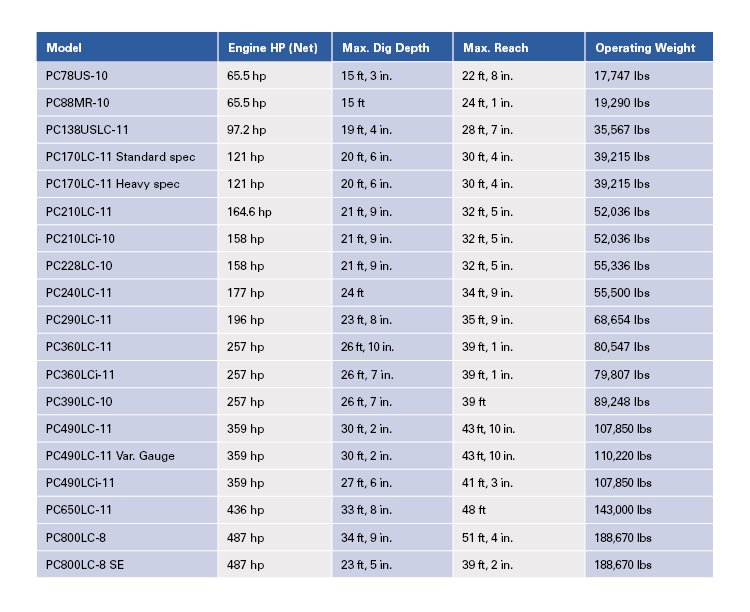

Today, Komatsu excavators offer more electronic control and easier maintenance and operator comfort than ever. Operators stay efficient, informed and situationally aware thanks to KOMTRAX machine monitoring as well as standard, rearview monitoring systems. Most of Komatsu’s excavators save fuel and offer quick response to operators’ demands because of a Closed Center Load Sensing (CLSS) hydraulic system. Many Komatsu excavators also feature an arm quick-return circuit, for faster cycle times. Komatsu currently offers 16 excavator models, including three intelligent Machine Control excavators — the PC210LCi-10, the PC360LCi-11 and the PC490LCi-11.

Product Spotlight: PC138USLC-11

Ideal for utility and highway applications, the new PC138USLC-11 hydraulic excavator features the same tight tail swing radius as its predecessor, and up to 4 percent less fuel consumption compared to the previous model. The new EPA Tier 4 Final certified model uses an SAA4D95LE-7 engine with a Komatsu Diesel Oxidation Catalyst (KDOC) and a SCR system with DEF injection. The engine requires no diesel particulate filter or regeneration.

The PC138USLC-11’s contoured cab profile and sliding door allow the cab to swing within the same radius as the counterweight. A larger counterweight mass remains standard, giving the PC138USLC-11 equal or better lift capacity than conventional models in the same size class.

Advice

“When working in underground utility, road construction or site development jobs, short-tail-swing excavators can significantly increase jobsite efficiency, especially when working in confined spaces,” says Justin Lantin, product marketing manager, excavators, for Komatsu America Corp. “When selecting a compact excavator, it’s important to evaluate lift and hydraulic capacities. Good lift is key to handling deck plates and trench boxes, but also important when using hydraulic attachments, such as hammers.”