What’s the Scoop: Case Excavators

From digging and backfilling to moving and placing pipe, the excavator is the go-to machine for utility contractors. To highlight these hard-working pieces of iron (as well as the companies that construct them), we’ve gathered the histories, product offerings and specs for the biggest names in the marketplace.

Over the next 10 pages, learn all about the product lines of the most popular excavator manufacturers in North America — from Caterpillar and John Deere to Komatsu and Volvo. Compare specs of different models or simply discover the beginnings of a brand you love. There are even insights and advice from industry insiders to aid in purchasing decisions and maintenance matters. Sit back, relax and dig in.

Pam Kleineke is managing editor of Utility Contractor.

Case Construction Equipment

A Full Range of Powerful, Tier 4-Compliant Machines

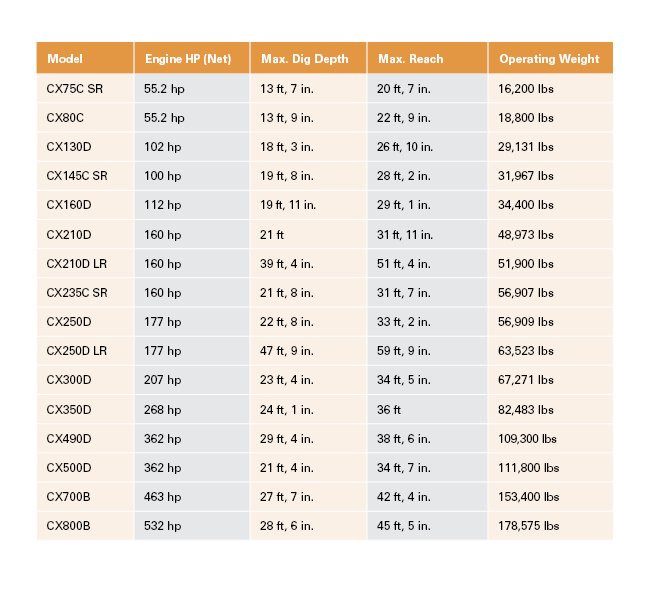

Case Construction Equipment is built on a foundation of innovation that dates back to the first threshing machines Jerome Increase Case built in 1842. Today, the company offers 16 mid- and full-size excavators ranging from 16,200 lbs (the CX75C SR) up to 178,575 lbs (the CX800B), with a combination of conventional, long-reach and minimum swing radius designs. According to the company, each Case excavator is engineered to provide an optimal combination of speed, power, operator comfort, control, reliability and support.

Product Spotlight: D Series

In 2015, Case introduced 10 new crawler excavators: the CX130D, CX160D, CX210D, CX210D Long Reach (LR), CX250D, CX250D Long Reach (LR), CX300D, CX350D, CX490D and the CX500D. These new models provide significant operational gains over their predecessors, including cycle times up to 12 percent faster, improved responsiveness and multifunctional control (simultaneous operation of boom while swinging, etc.), up to 6 percent greater breakout forces and up to 14 percent greater fuel efficiency.

Case D Series excavators meet Tier 4 Final emissions standards through an innovative combination of cooled exhaust gas recirculation (CEGR), selective catalytic reduction (SCR) and diesel oxidation catalyst (DOC) technologies, which helps maximize uptime and performance — all with minimal maintenance. There is no diesel particulate filter (DPF), no DPF regeneration or associated lifetime service costs.

The Case Intelligent Hydraulic System (CIHS) relies on four integrated control systems to make the best use of the machine’s hydraulic power and momentum. This helps these excavators exert only the power and force required for the task at hand, while also improving important performance metrics such as increased lifting power and faster cycle times. This also results in fuel savings, reduced wear and tear on the machine and easier operation.

Advice

“When considering the purchase of a new excavator, be sure to talk to your dealer about machine warranties and available extended maintenance contracts,” says John Bauer, brand marketing manager for Case Construction Equipment. “When it comes to purchasing new equipment, protecting your investment is one of the most important considerations. Most manufacturers offer standard warranties on their equipment, but a premium service/maintenance program will make a significant impact on your overall cost of ownership.”