HDD Manufacturers Are Ready to Tackle the Workforce Shortage and Train New Drillers

The utility construction industry has seen its fair share of obstacles over the past few years — from the recession to burdensome regulations to lack of funding. And now? It’s the shortage of qualified workers. Bids are being won and demand is steadily picking up, but workers are nowhere to be found. Although this is a problem among all types of contractors, the horizontal directional drilling (HDD) market has been significantly impacted. With plenty of work to be done, contractors are eager to hire. However, not any worker will do. Companies need skilled, qualified operators to tackle the work.

“HDD operators are in high demand throughout the utility construction market,” says Greg Wolfe, Ditch Witch director of training. “This high demand is leading to a shortage of operators with proper training and the right skill set, creating a gap that needs to be filled. As the underground construction market continues to grow, connecting with the next-generation workforce and retaining experienced operators through effective training is a priority.”

To combat the growing problem, HDD manufacturers such as Ditch Witch, Vermeer and Toro have been answering the call for help. This has involved developing training programs to entice and prepare operators for a future in the field. From programs for newbies and refreshers for veteran operators to classroom, onsite or computer training, there’s something for every student’s skillset and learning preference.

Vermeer has recently partnered with Des Moines Area Community College for its HDD Circuit training program — a two-week, 72-hour course held at the company’s global HQ.

What’s Out There?

While most HDD manufacturers have been offering training for decades, efforts have certainly evolved over the years. Now, there are even more options available to groom the perfect driller.

Vermeer, a leading HDD manufacturer, has been training customers for years with a mix of classroom and on-the-job programs for new and seasoned contractors. Most recently, the company has partnered with Des Moines Area Community College (DMACC) for its HDD Circuit training program. The two-week, 72-hour course is conducted at the company’s global headquarters and is currently the only program of its kind offered through an accredited college.

“Municipalities are beginning to recognize the liability that’s involved with issuing work to contractors who are not using qualified or well-trained operators,” says Tony Bokhoven, training manager at Vermeer. “We’ve all seen the catastrophic consequences from drilling and striking a gas main in the news. They’re starting to ask about what kind of training do these operators have before they start the work. To help with this, we took our curriculum to DMACC and they evaluated the material from start to finish. Now, DMACC is endorsing our program and offering a certification upon completion.”

According to Vermeer, the HDD Circuit was not only designed to train operators, but create drillers. The program takes students through the whole drilling process — from walking the bore plan, locating utilities, identifying ground conditions, etc. — by combining classroom instruction, simulator use and onsite experience.

“We have an 11 ½-acre demo site that is set up like a real jobsite,” says Bokhoven. “There are utilities buried in the ground and obstacles to steer around. All of these things make it very realistic to the conditions an operator will encounter when they’re drilling on a real jobsite. However, the benefit is that it’s not a real jobsite in the sense that traffic isn’t whistling by and they don’t have a timeline to get the job done. I tell all of my classes, ‘This is your opportunity to get it wrong without any consequences and then figure out how to do it right.’”

Josh Beddow, marketing manager for The Toro Co., says that HDD manufacturers are always looking at ways to make their machines easier and more comfortable to operate, including less exposure to noise and vibration.

Ditch Witch has been providing factory-certified training since 1989 to operators of all skill levels in a variety of methods. The company’s program includes online and classroom-led courses, training on-site at the Ditch Witch factory in Perry, Okla., dealer-led training and new digital and virtual reality simulator training.

“In an effort to connect with the next generation of technology-savvy operators, last year we launched an online HDD training program which extends the Ditch Witch on-site, classroom-style training,” says Wolfe. “This program allows novice operators to train online at home, in a dealership or on a mobile device. Anyone interested in the program can register online and take the courses at their convenience, as many times as needed.

“In addition, we recently added a virtual reality component to our HDD training program. The new Ditch Witch virtual reality HDD simulator offers trainees a virtual drilling environment to best replicate a real HDD jobsite, from urban to rural settings — all while allowing the user to sit in a virtual drill cab and use real joystick control technology to operate.”

Toro offers training that’s tailored to its customers’ specific needs, complete with field training specialists to support its dealers. These specialists spend time with a contractor to ensure they’re comfortable and confident in operating and servicing the machine. Josh Beddow, Toro’s marketing manager, points out that the company’s training goes beyond newbies and is especially useful to veteran operators who may be switching to newer equipment.

“Operators tend to get so comfortable with their older piece of equipment — how it sounds and feels — that they may need training to get used to a new machine,” he says. “The new piece will sound and feel differently, as well as have new tools and settings to help them increase their productivity. We try to educate them on how to use those new technologies and features to benefit the operation of the equipment. For example, some Tier 4 machines come with regen cycles, so that’s another area where learning is involved. We explain what it is and why it’s important, so operators can be in tune with the machine.”

Promoting the Industry

According to all three manufacturers, the demand for HDD installations is strong and is projected to only continue growing. With that, it’s important to promote the industry to potential students early on and continue to highlight the bright future the market has ahead.

“Whether it’s been finding people to work in our manufacturing facilities or out in the field as a contractor, we’ve found that you have to engage these people earlier,” says Bokhoven. “For example, we used to engage juniors and seniors in high school and talk to them about welding, manufacturing and construction. However, we’ve found that if you haven’t engaged them by the time they’re freshmen, you’re probably too late.

“The future of the HDD industry is very strong. It’s changed from the respect that it used to be just a job that made a decent living. Now, with the right person who wants to travel and work outside, you can make a great career out of it and make a very strong living.”

Pam Kleineke is managing editor of Utility Contractor.

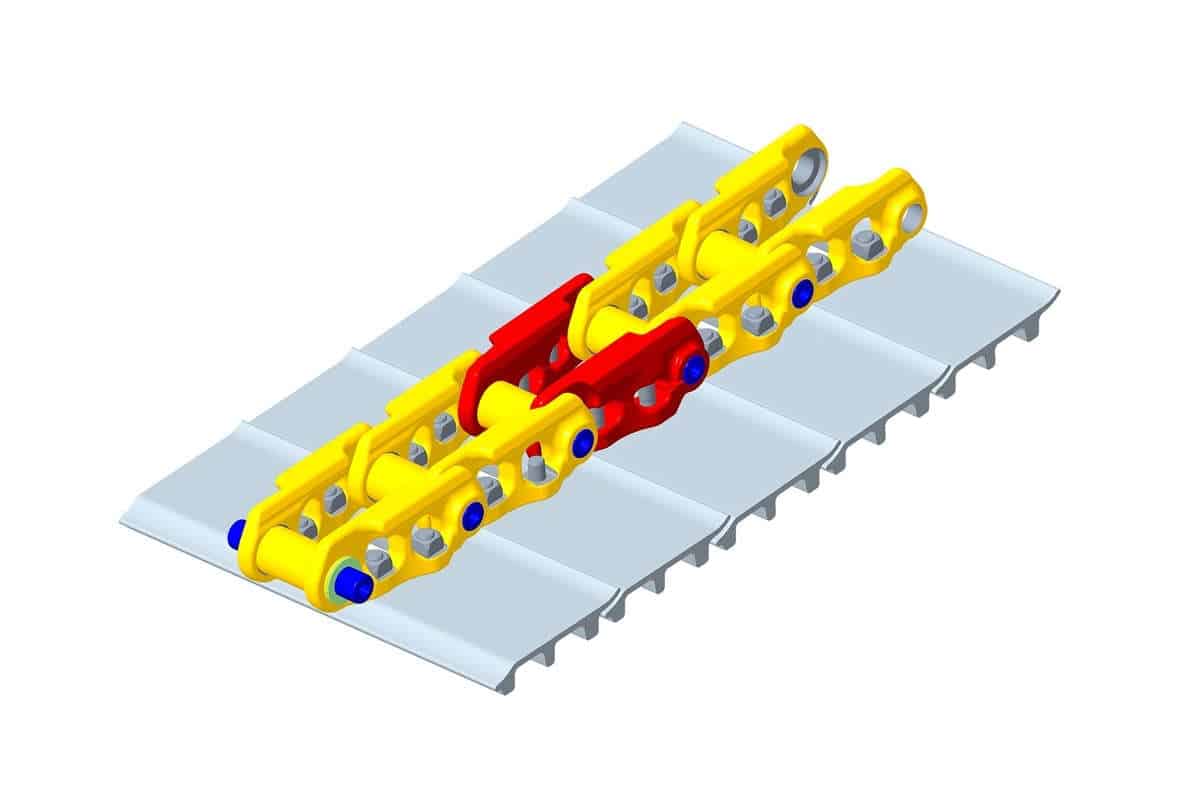

Three New HDD Models in the Market

Ditch Witch

Ditch Witch

Toro

Toro

Vermeer

Vermeer

For more articles on horizontal directional drilling, click here. Tags: Ditch Witch, Horizontal Directional Drilling, March 2017 Print Issue, Toro, Vermeer